Table of Contents

- Evolving Vehicle Technologies

- The Importance of Certification

- Technological Integration in Training Programs

- Addressing the Skills Gap

- The Need for Standardized Training for EV Technicians

- Data-Driven Approaches to Technician Training

- Conclusion

The auto repair industry is experiencing an unprecedented transformation, propelled by new technologies and increasing vehicle complexity. Automotive professionals are finding themselves at the forefront of an era where advanced diagnostic tools, electrification, and software-driven vehicle systems are quickly becoming the norm. With this shift, recognized credentials such as icar gold class have emerged as essential markers of expertise and quality in automotive service, assuring customers and employers that technicians possess up-to-date skills and a commitment to ongoing education.

Staying competitive as a technician—or as a repair facility—now relies on much more than hands-on experience. Formal training programs and certification standards ensure that those who diagnose, service, and repair vehicles meet rigorous, industry-approved criteria. As vehicles incorporate more advanced driver-assist systems and electric drivetrains, organizations and regulators are focusing on ways to certify technicians for both current and next-generation needs, supporting safe and reliable care for all the innovations on the road.

Evolving Vehicle Technologies

Automotive technology is evolving rapidly, introducing new challenges for repair professionals. Modern vehicles feature systems like Adaptive Cruise Control (ACC), Lane Keeping Assist (LKA), and a range of semi-autonomous capabilities that require specialized diagnostic and repair knowledge. According to the U.S. Bureau of Labor Statistics, workshops nationwide are investing in updated technology and technical training to keep pace with cars that now more closely resemble computers on wheels than the purely mechanical vehicles of decades past.

Training interventions specifically focused on these new systems are proving their value by reducing errors in repair and calibration, which are vital for both safety and vehicle performance. As features like automated emergency braking and predictive maintenance become mainstream, technicians without current knowledge or credentials risk falling behind as vehicle technology leaps ahead.

The Importance of Certification

Certification serves as the backbone of professional credibility for technicians and auto shops alike. ASE and similar organizations advocate for continuous education, aligning with broader workforce trends that emphasize skills verification and measurable outcomes rather than purely tenure-based advancement. Credentialing also acts as a bridge between evolving regulatory guidance and real-world practice. As federal and state transport authorities increasingly rely on industry-driven standards to validate technician competence, certifications ensure that critical safety procedures and technical requirements do not slip through the cracks, especially as vehicles become more complex and interconnected.

Technological Integration in Training Programs

The auto repair training landscape is experiencing a revolution, fueled by innovations in educational technology. Virtual Reality (VR) platforms, interactive simulators, and sophisticated e-learning modules are now part of the mainstream curriculum in many technical schools and professional training centers. VR, for instance, allows students to practice engine assembly and troubleshooting in risk-free, highly realistic environments—making mistakes and learning from them without the consequences of damaged hardware or safety hazards.

Addressing the Skills Gap

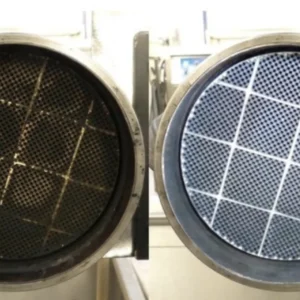

The adoption of electric vehicles (EVs) and advanced hybrids is creating an urgent demand for new skill sets in the automotive workforce. Yet, a shortage of qualified technicians continues to plague the industry.

Training programs are actively adapting their curricula to attract more students and equip them with the specific knowledge needed to diagnose and service electrical architectures, battery management, and specialized drivetrains, further cementing the value of certified expertise in shop operations.

The Need for Standardized Training for EV Technicians

As electric vehicles claim a larger share of new car sales, there is a notable absence of nationwide, standardized requirements for EV technician training in the United States. This gap threatens to slow the deployment of crucial EV charging networks and delay the adoption of new technology in commercial and public vehicle fleets. Experts urge the creation of consistent, federally recognized guidelines to ensure that all technicians working with high-voltage EV components are adequately trained and certified—protecting consumers, workers, and the broader energy infrastructure as the country accelerates towards clean transportation.

Data-Driven Approaches to Technician Training

Real-time data and analytics increasingly power modern training programs. Adaptive learning platforms monitor student progress and proficiency, automatically tailoring lesson pacing and content delivery to individual learner needs. By leveraging performance metrics, shop owners and educators can quickly identify knowledge gaps and retrain staff or students accordingly.

This level of personalization drives greater retention and ensures that technicians emerge from programs not only with a credential but with capabilities that match the demands of real-world repair scenarios.

Conclusion

The auto repair industry stands at a crossroads, where continuous advancement in training and certification standards is no longer optional but essential. As vehicles grow increasingly sophisticated, so must the professionals who keep them safe and roadworthy. Ongoing investment in technology-enhanced education, robust certification programs, and nationally recognized standards will underpin the success and trustworthiness of every repair facility and technician in the years to come.